The processing of metal sheets generally includes cutting, welding, drilling and other methods. Among them, drilling processing is more complicated and requires higher equipment.

Traditional drilling methods include stamping, drilling with drills, etc. Nowadays, with the advancement of science and technology, laser head drilling has gradually become popular. Laser head drilling has many advantages. The laser head can drill almost any thickness of plate. The drilling speed is hundreds of times that of drilling. The cutting surface is double-sided. They are all smooth and can be punched in any shape drawn by computer.

Laser drilling is a laser processing technology that has been put into practical use very early and is also one of the main application areas of laser processing. Traditional processing methods for materials with high hardness and high melting point can no longer meet certain process requirements. This type of processing task is difficult, sometimes even impossible, with conventional machining methods, but it is not difficult to achieve with laser drilling.

The laser beam is highly concentrated in space and time. Using lens focusing, the spot diameter can be reduced to the micron level to obtain laser power density. Such high power density enables laser drilling in almost any material. And compared with other conventional drilling methods such as mechanical drilling and electric discharge machining, it has the following significant advantages: laser drilling speed is fast, high efficiency, and good economic benefits.

Since laser drilling uses a high-energy laser beam with a power density to act on the material instantaneously, the action time is only 10-3-10-5s. Therefore, laser drilling is very fast. By combining high-efficiency lasers with high-precision machine tools and control systems, and program-controlled by microprocessors, high-efficiency drilling can be achieved. Laser drilling and EDM drilling can be performed on different workpieces. Compared with mechanical drilling, the efficiency is increased by 10-1000 times.

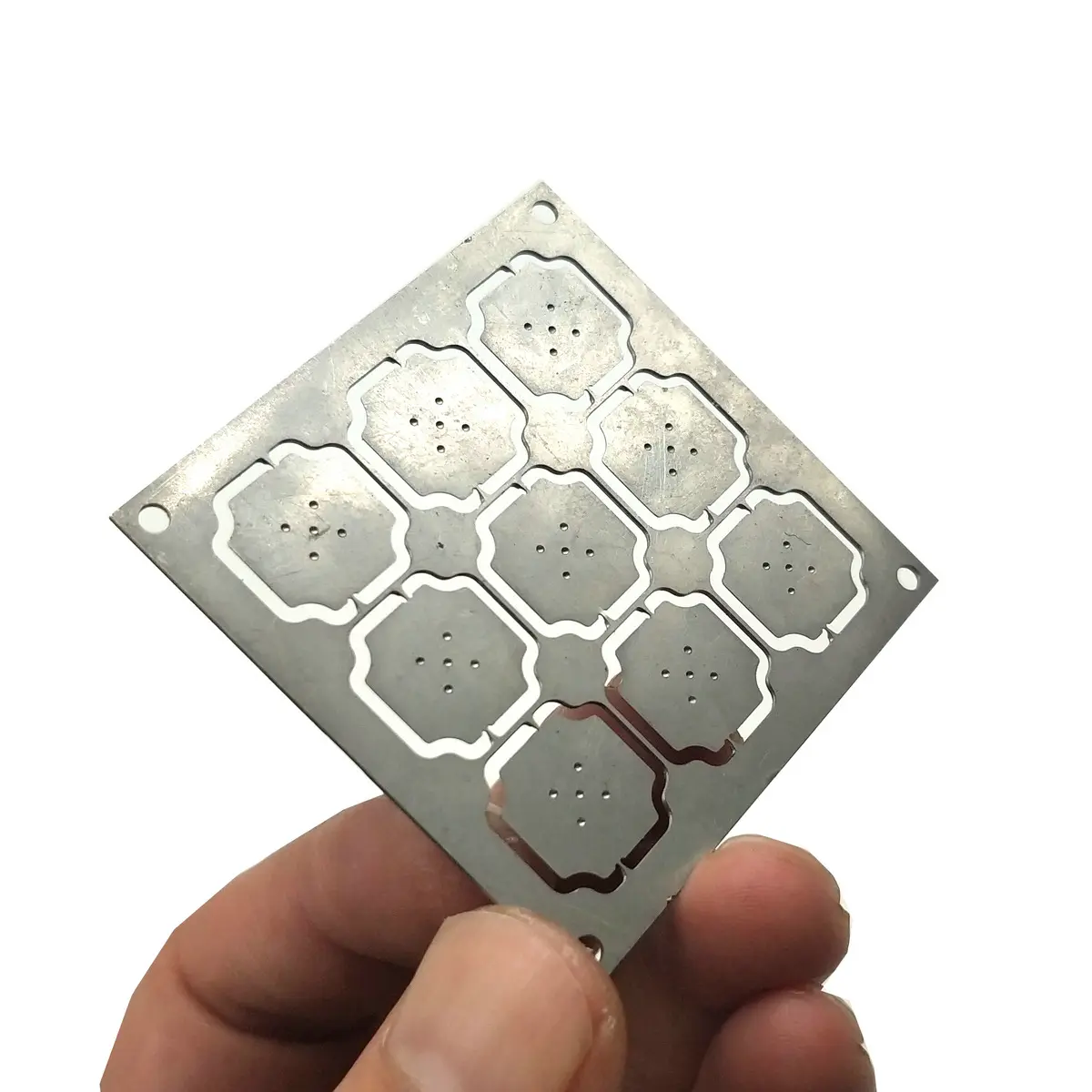

As the demand for high-precision processing increases, related precision processing technologies are also developing rapidly, among which laser precision drilling technology is gaining more and more recognition in the market. At present, laser precision drilling is the most widely used in the PCB industry. Compared with the traditional PCB drilling process, laser processing on PCB is not only fast, but also can achieve small holes, micro holes and invisibility below 2 μm that cannot be achieved with traditional equipment. Drilling of holes. On the surface of electronic products, it can also be used for drilling holes in mobile phone speakers, microphones and other glass.

If you need to know more, you can click on our website: https://www.laserdt.com/

The Laser Marker Brings Massive Changes to the Metal Industry.