Edible oil is an indispensable consumable in people’s lives. With the continuous improvement of living standards, people’s pursuit of the quality of edible oil is increasing day by day. The laser inkjet marking on edible oil barrels has become a mark of edible oil quality. Laser inkjet coding is widely used in the field of marking due to its high efficiency, non-alterability, no consumables, and no pollution. It can mark each barrel of edible oil. Marking different information such as specifications, production date, batch number, etc. is a basic and necessary means to ensure the quality of edible oil.

Traditional laser coding edible oil detection is mainly done manually, but the human eye has limitations in detection. In order to adapt to the standards of modern production, the quality inspection level of the edible oil production process must be improved. Laser application in the edible oil industry The inkjet coding visual sorting system uses advanced machine vision and automated control technology to perfectly replace manual inspection and improve inspection speed and accuracy.

The visual inspection and sorting system relies on knowledge in machine vision, computer application science, automatic control and other subject areas. In layman’s terms, it uses cameras to replace the human eye, and image processing and algorithm functions to replace the human brain to extract and analyze features of targets. It is an artificial intelligence technology that can then make judgments to control the production process.

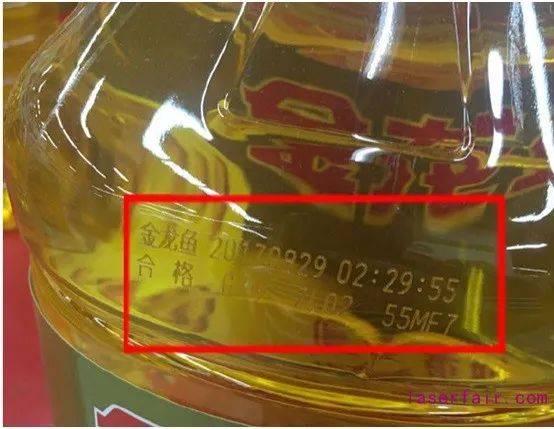

The edible oil laser inkjet coding visual inspection and sorting system flexibly uses various technologies and algorithms to quickly and accurately detect the inkjet information and compare it with the information that should be inkjet in the laser inkjet printer to achieve edible oil laser inkjet coding. Visual inspection and automatic sorting functions replace manual sorting, improve production efficiency and automation levels, liberate labor, and reduce production costs. Once misprinting, missing printing, defacement, overlap, skew, etc. are discovered, the visual system will automatically alert the user and can execute preset automatic control program actions to eliminate unqualified products.

Exploring The Diverse Applications Of Laser Cleaning Technology

Flying Laser Printer and the Significance of Code Marking in Industry