Co2 Flying laser marking machine

PRODUCT DESCRIPTION

The D9 series CO2 flying laser printer is a high-speed continuous marking model designed to increase productivity with the Dawei CO2 laser. Higher security , good optical mode , fast processing efficiency , 100 3MM high 2D codes per minute , and 100 production date digital codes per minute , providing high-speed , high-volume applications for marking needs , mainly in production date , anti-counterfeiting , pharmaceutical and food packaging industries . This model supports automatic coding , serial number , batch number , date , barcode , 2D code , automatic number skipping and other functions to meet the needs of customers in different industries .

The D9 series CO2 flying laser printer is a high-speed continuous marking model designed to increase productivity with the Dawei CO2 laser. Higher security , good optical mode , fast processing efficiency , 100 3MM high 2D codes per minute , and 100 production date digital codes per minute , providing high-speed , high-volume applications for marking needs , mainly in production date , anti-counterfeiting , pharmaceutical and food packaging industries . This model supports automatic coding , serial number , batch number , date , barcode , 2D code , automatic number skipping and other functions to meet the needs of customers in different industries .

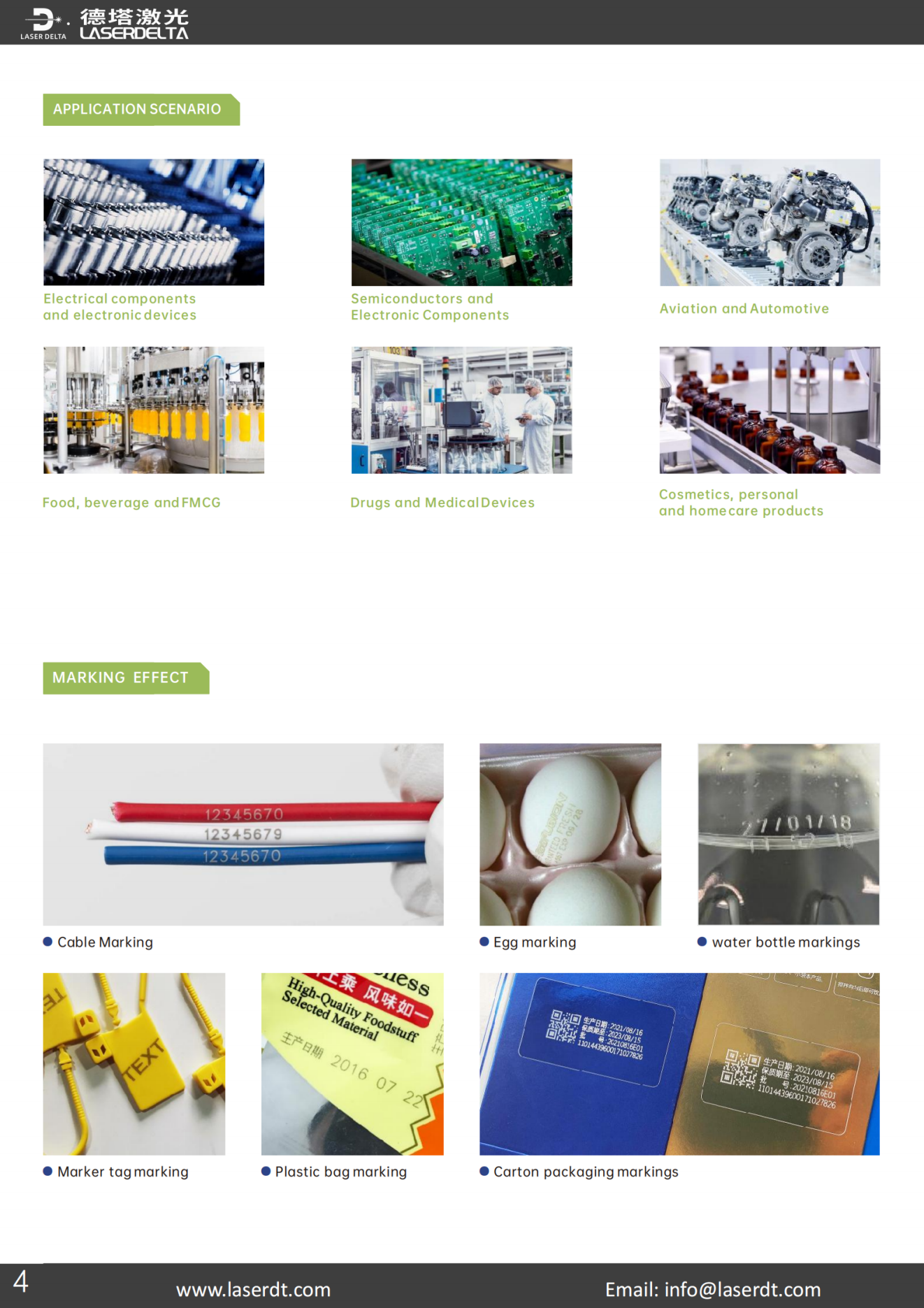

Co2 flying laser printer is suitable for online marking of most non- metal materials , such as paper packaging , film packaging , coated metal , organic glass , resin , plastic , bamboo and wood products , PVC products , etc . Widely used in food and beverage packaging , alcohol , dairy products , clothing accessories , leather , electronic components , pharmaceuticals , personal care products , tobacco , chemical building materials products and other fields of production and effective date , batch number , shift , manufacturer name and logo and other graphics and text marking.

PRODUCT DISPLAY

Co2 Flying laser coder series

The D9 series uses a Dawei CO2 laser. The guarantee is higher and based on the waveguide technology of compact and integrated design, it is the product with high quality power/size ratio in the market. Because its RF driver is integrated in the laser head, the system is not only compact, but also more stable and ideal for normal operation in various harsh industrial environments.

The D9 series uses a Dawei CO2 laser. The guarantee is higher and based on the waveguide technology of compact and integrated design, it is the product with high quality power/size ratio in the market. Because its RF driver is integrated in the laser head, the system is not only compact, but also more stable and ideal for normal operation in various harsh industrial environments.

PRODUCT PARAMETER

| Model Series | A Series | |||

| Model | D9-D30 | D9-D32 | D9-D33 | |

|

Laser parameters |

Laser Model | D40 | D40i | D40i |

| Output power | ≤40W | ≤38W | ≤30W | |

| Beam quality M² | ≤2 | ≤2 | ≤2 | |

| Pulse repetition frequency | 0-25KHZ | |||

| Laser wavelength | 10.6um | 10.2um | 9.3um | |

| Output power stability | <5% | |||

| Design life | Approx. 30,000 operating hours (non-life time) | |||

|

Optical properties |

Marking range | 50 ~300mm (range optional) | ||

| Engraving depth | ≤1mm (depending on power and time) | |||

| Engraving speed | ≤10000mm/s | |||

| Repetition accuracy | ±0.002 | |||

| Minimum marker line width | 0. 1mm | |||

| Minimum character height | 0.15mm | |||

|

Usage environment |

Cooling method | Built-in air cooling | ||

| System power supply | 800W / 220V / 50Hz(can be connected to 110V) | |||

| Temperature, humidity | 0 ~40 ~40°, 30% ≤RH≤85%, need to install air conditioning when using beyond the range | |||

| Oil mist, condensation | Not allowed | |||

|

Other parameters |

Operating System | Flying coding system | ||

| File format | The software supports text, 2D codes, bar codes, running numbers, graphics and other marking content | |||

| External dimensions | 660X510X1460 mm | |||

| Packing size | Mainframe: 780X330X280 mm Stand: 1340X340X240 mm | |||

| Net weight of the whole machine | About 16.5KG; about 40KG with stand | |||

| Gross weight | About 19.5KG; including the bracket about 45.3KG | |||

D9 Series Co2 Flying laser coder series

With the development of the national economy to drive the progress of various industries , assigning code marking equipment plays a pivotal role in the production line . Code marking equipment through the packaging to show the unique personality of the product , is a key part of the enterprise to win the trust of consumers.

Through marking equipment on the three periods ( production date , expiration date , batch number) and trace a bility code give n to eac h product is the demand of various industries , especially the fast moving consumer goods industry , the current main processing methods for inkjet and laser spray code.

PRODUCT FEATURE

MARKING SPEED UP TO 200 METERSPER MINUTE

MARKING SPEED UP TO 200 METERSPER MINUTE

THE INDUSTRY’S FASTEST MARKING SPEED LASER CODING SYSTEM, MARKING SPEEDOFUPTO 200 M / MIN (SINGLE LINE 2MM WORDHEIGHT

NUMBERS AND LETTERS) FOR USE ON MEDIUM OR HIGH SPEED PRODUCTION LINES

RELIABLE AND DURABLE LASER SOURCE

RELIABLE AND DURABLE LASER SOURCE

Adopt Dawei CO2 laser. Higher assurance, uniform laser power density, highly focused laserbeam

Achieves better marking contrast and laser design life up to 30,000 hours

ULTRA-COMPACT DESIGN AND FLEXIBLE CONFIGURATION

ULTRA-COMPACT DESIGN AND FLEXIBLE CONFIGURATION

SIMPLE INTEGRATION, REDUCED INSTALLATION COSTS, AND INCREASED POSITIONINGFLEXIBILITY WITH THE INDUSTRY’S INNOVATIVE COMPACT LASER CODER MARKINGHEADINSTALLATION COSTS AND INCREASED POSITIONING FLEXIBILITY

FLEXIBLE INSTALLATION METHOD, EASY TO ADJUSTTHE INSTALLATION POSITION

FLEXIBLE INSTALLATION METHOD, EASY TO ADJUSTTHE INSTALLATION POSITION

THE FLYING MODEL IS DESIGNED FOR HIGH-SPEED PRODUCTION LINE, WHICH CAN BE FLEXIBLY COMBINED WITH THE PRODUCTION LINE INSTALLATION. UP AND DOWN, LEFT AND RIGHT MOVEMENT ADJUSTMENT, MARKING HEAD CAN ALSO BE ROTATED 360 ° MARKING

|

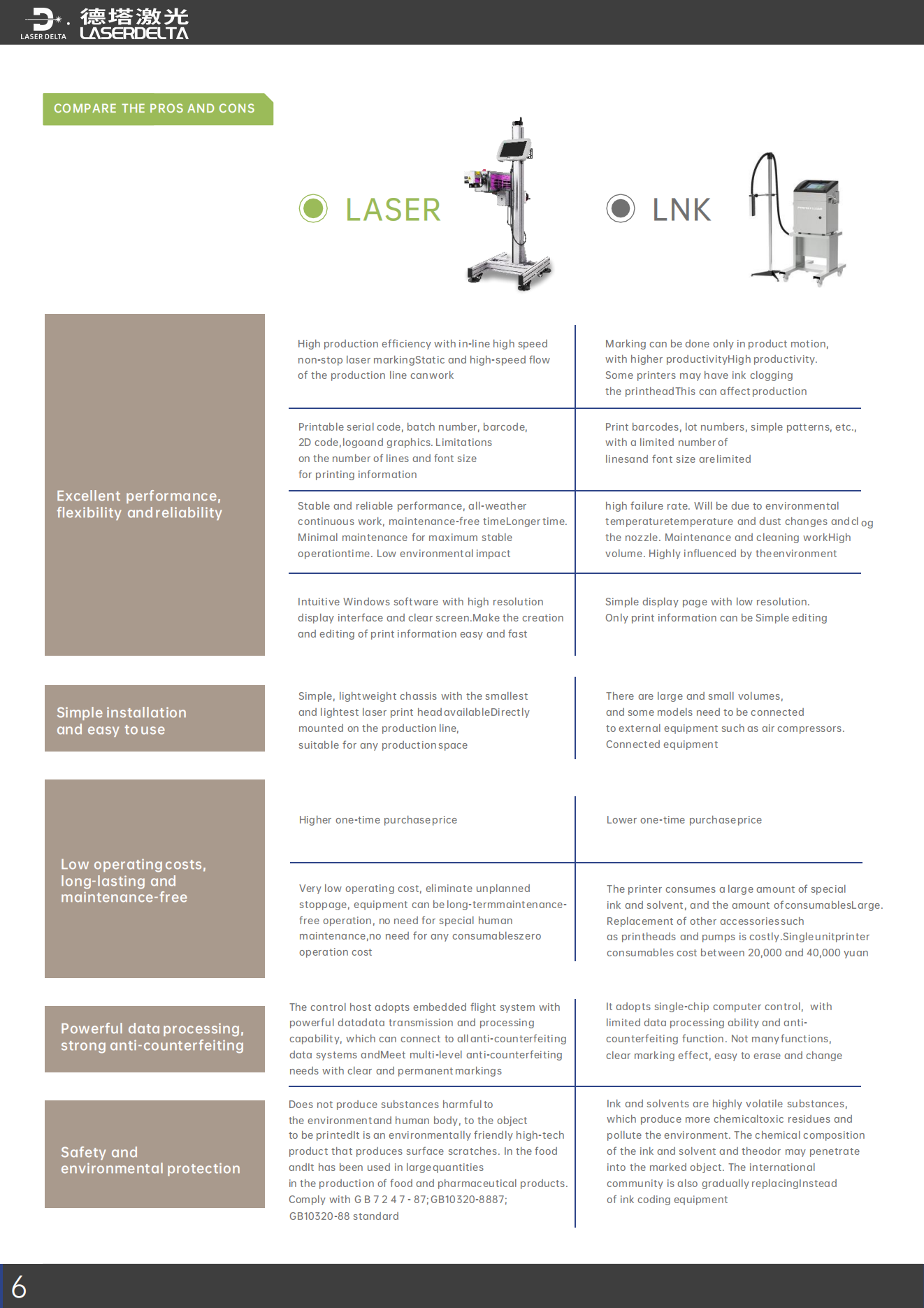

Excellent performance, flexibility and reliability |

High production efficiency with in-line high speed non-stop laser marking Static and high-speed flow of the production line can work | Marking can be done only in product motion, with higher productivity High productivity. Some printers may have ink clogging the printhead. This can affect production |

| Printable serial code, batch number, barcode, 2D code, logo and graphics. Limitations on the number of lines and font size for printing information | Print barcodes, lot numbers, simple patterns, etc., with a limited number of lines and font size are limited | |

| Intuitive Windows software with high resolution display interface and clear screen. Make the creation and editing of print information easy and fast | Simple display page with low resolution. Only print information can be Simple editing | |

|

Simple installation and easy to use |

Simple, lightweight chassis with the smallest and lightest laser print head ,available directly mounted on the production line, suitable for any production space | There are large and small volumes, and some models need to be connected to external equipment such as air compressors. Connected equipment |

|

Low operating costs, long-lasting and maintenance-free |

Higher one-time purchase price | Lower one-time purchase price |

| The operating cost is extremely low, unplanned downtime is eliminated, and the equipment can operate maintenance-free for a long time. No dedicated maintenance is required, no consumables are required, and zero operating cost. | Printers consume large amounts of special materials

Consumables such as ink and solvent are used in large quantities. Replacing nozzles, pumps and other accessories is more expensive. The cost of consumables for a single printer is between 20,000 and 40,000 yuan. |

|

|

Powerful data processing, strong anti-counterfeiting |

The control host adopts an embedded flight system

Powerful data transmission and processing capabilities Ability to connect to all anti-counterfeiting Data system and meet multi-level anti-counterfeiting Requires clear and permanent markings |

It adopts single-chip computer control, with limited data processing ability and anti- counterfeiting function. Not many functions, clear marking effect, easy to erase and change |

|

Safety and environmental protection |

Does not produce substances harmful to the environment and human body, to the object to be printed. It is an environmentally friendly high-tech product that produces surface scratches. In the food and It has been used in large quantities in the production of food and pharmaceutical products. Comply with G B 7 2 4 7 – 87; GB10320-8887; GB10320-88 standard | Inks and solvents are highly volatile substances that produce more toxic chemical residues and pollute the environment. The chemical composition and solvents of inks and solvents may penetrate into the marked object. The international community is also gradually replacing inkjet coding equipment. |