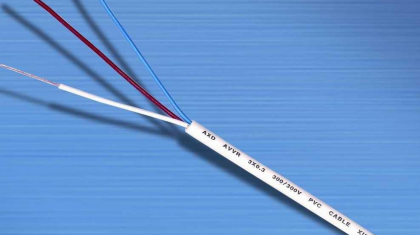

In the cable industry, in order for products to be able to distinguish product brands, identify product types, count meters, etc., there will be various signs on cables. Most cable manufacturers now use inkjet printers for coding. Ink printing causes pollution, high usage costs, and huge ink consumption. It is understood that a medium-sized enterprise spends 400,000 to 500,000 or even millions on ink purchases per year. And with the improvement of industry requirements, ink jet coding can no longer meet industry requirements.

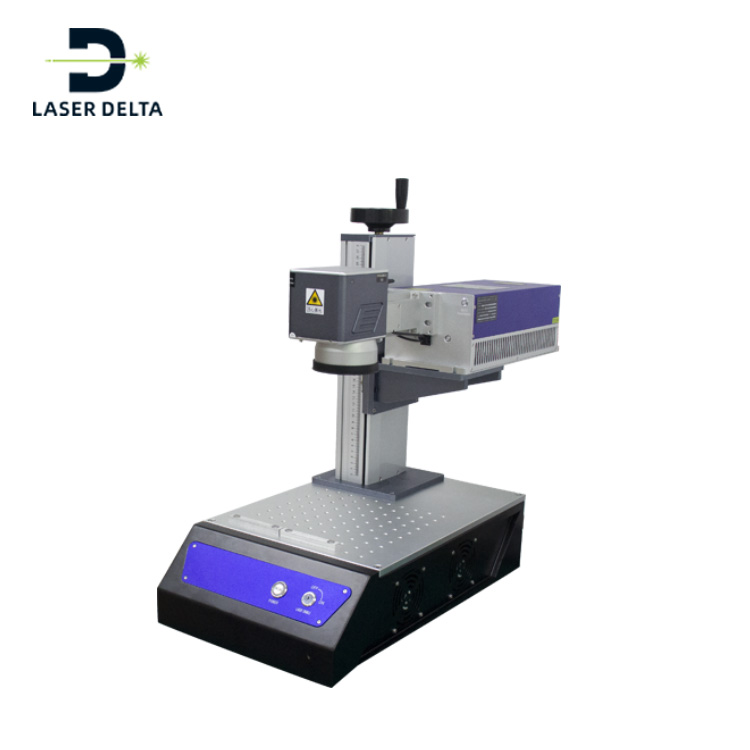

Nowadays, laser marking machines (aliases: laser coding machines, laser inkjet printers) have entered the cable industry. With its outstanding advantages, lasers can meet the industry’s requirements for clarity and durability, and are very popular in the cable industry. . Laser inkjet printers are used in the cable industry, which means that once the date, batch number, brand, serial number, QR code and other marks of cable products are sprayed on, they can no longer be changed, which plays a greater anti-counterfeiting role; it means that some parts can be resisted Counterfeiting prevents unscrupulous manufacturers from taking advantage of it; it means that it can play a certain role in resisting the chaos in the wire and cable industry, thereby improving the quality of wire and cable products. The initial investment cost of laser coding equipment will be higher, but it does not require any consumables and consumes relatively low power, which will definitely bring many benefits in the long run.

At present, the lasers used in cable inkjet printing are mainly divided into: carbon dioxide laser marking machines, fiber laser marking machines, and ultraviolet laser marking machines.

Among them, carbon dioxide laser marking machines and fiber laser marking machines burn the surface of the cable to cause discoloration, which will cause damage to the surface of the cable and produce smoke.

The ultraviolet laser marking machine has a short wavelength of 355nm and is a cold laser. It mainly produces discoloration by breaking the chemical molecular bonds of the plastic on the surface of the cable without damaging the surface of the cable. And it is adaptable to a variety of materials. In the future, more and more cables will use UV laser marking machines for coding.

UV marking machine

Fiber laser marking machine

Laser marking uses a laser beam to mark permanent marks on the surfaces of various materials.

Ultraviolet laser is a “cold process” that can break the chemical bonds in materials (especially organic materials) or surrounding media, causing the material to undergo non-thermal process damage to achieve a discoloration reaction. This kind of cold processing has special significance in laser marking processing, because it is not thermal ablation, but cold peeling that breaks chemical bonds and does not produce “thermal damage” side effects. Therefore, it does not affect the inner layer and nearby areas of the processed surface. Produces heating or thermal deformation.

Currently, in non-transparent plastic products, soft film packaging, cable pipes and other industries, UV has good applications due to its good absorption and low thermal damage.