Acrylic material is widely used. Its material is cheap and has good laser absorption rate. It can be used to make various products, including various signs, gifts, prizes and other items. Most people usually choose clear acrylic because of its popularity and ease of use.

This kind of transparent acrylic is generally engraved using carbon dioxide laser, which is determined based on the characteristics of light. The wavelength of carbon dioxide laser is 9.2-10.8μm. Carbon dioxide laser can also be called molecular laser.

To use laser engraving acrylic material, we need to first understand the general classification of the material. Acrylic generally refers to heat-sensitive plastic manufactured by various brands. Acrylic boards are divided into two categories: cast boards and extruded boards according to production technology.

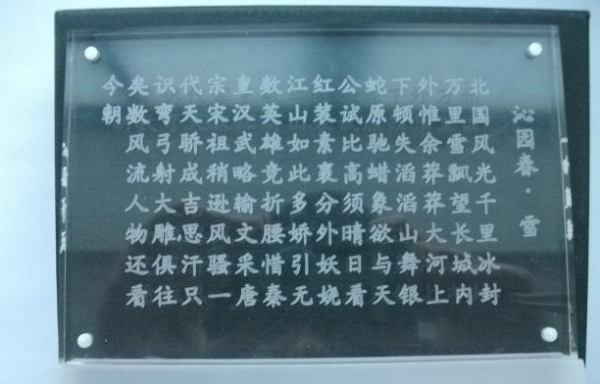

Cast Acrylic Sheet: High molecular weight, excellent stiffness, strength and excellent chemical resistance. This kind of board is characterized by small batch processing, unparalleled flexibility in color systems and surface texture effects, and complete product specifications, suitable for

for various special purposes. (When laser engraved, cast acrylic transforms into the icy material sought after in many custom applications. It can be molded into different shapes and sizes, and it is often used to create awards due to its good optical qualities.)

Acrylic extruded board: Compared with cast board, extruded board has lower molecular weight and slightly weaker mechanical properties. However, this feature is beneficial for bending and thermoforming processing, and is beneficial for rapid vacuum molding when processing larger sheets. At the same time, the thickness of the extruded plate

Tolerances are smaller than cast plates.

It is easier to make extruded acrylic than cast acrylic, which makes extruded acrylic cheaper. Additionally, extruded acrylic is laser-engraved clean and smooth, with flame-polished edges. Laser engraved products look clear and not like cast acrylic

Matte look after engraving. It is also softer in comparison and sticks easily during the rotary carving process.

Laser engraving acrylic works best at low power and high speed. If your acrylic has coatings or other additives, increase the power by 10% but maintain the speed you would use on unpainted acrylic. This gives the laser more energy to cut

paint. The materials discussed will determine the ideal frequency setting for your laser. However, if using cast acrylic, you can engrave with high frequencies of 10,000 – 20,000 Hz, and if using extruded acrylic, you may want to engrave with 2,000 – 5,000 Hz

of lower frequency engraving. Lower frequencies result in low pulses, which increase the pulse energy or reduce the constant energy in the acrylic. This phenomenon results in less boiling, less flames, and slower cutting speeds.

What variances exist among laser marking machines of varying power levels?